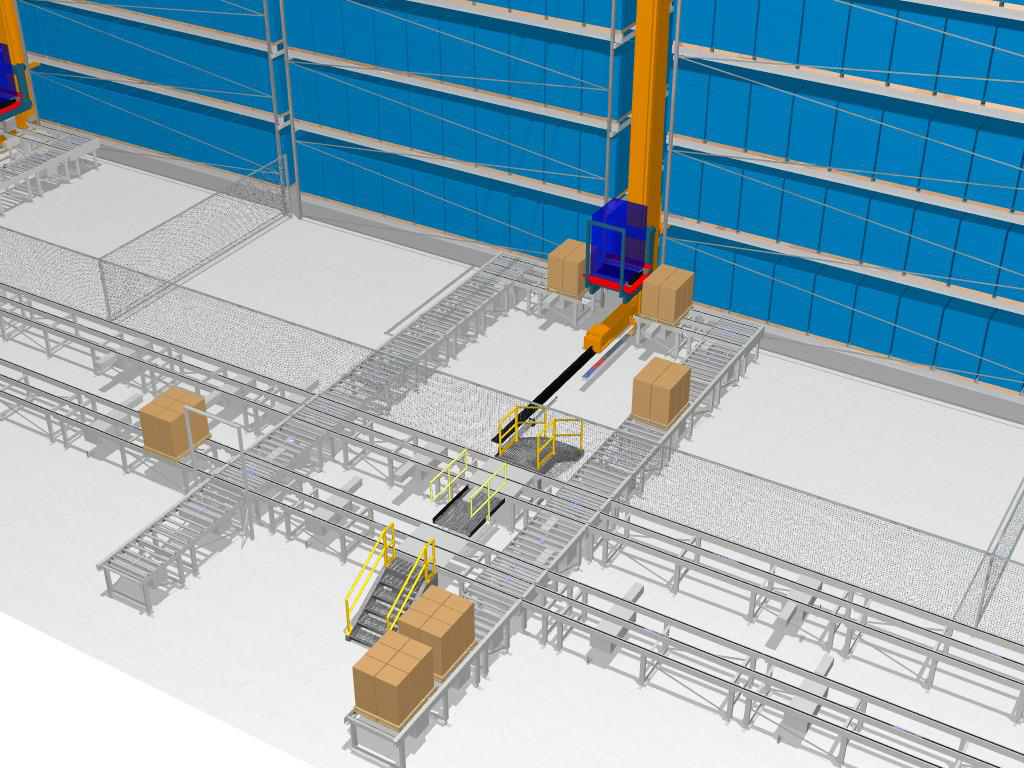

Automatic Storage Retrieval Systems that incorporate AI are valuable systems being used for cold storage facilities, manufacturing, warehouses, and distribution centers throughout the world 24/7. The capabilities of these systems are proving to be extremely valuable for general contractors, architects, developers, and owners in the commercial/industrial construction ecosystem.

When deciding on the type of ASRS system your organization needs, the following should be considered:

- Number of stock item type

- How many of each item

- Throughput rate

- Physical size and weight of each item

- Cold storage temperature controls for chilled, deep-frozen foods, and perishables

- Clean room environment

- Growth expectations

There are many benefits of ASRS systems.

Switching to an automated warehouse storage system from a forklift or fully manual system can vastly improve product handling efficiency and provide a safer warehouse. Some systems even operate in an efficient “lights-out” environment. They are designed for mission critical applications to ensure easy maintenance and maximum uptime.

When your inventory is organized, you get better visibility of stock levels, faster fulfillment of orders, and improved space utilization. Each type of storage offers a different level of density, with highly automated solutions offering the best density. The right storage solution for your needs can have a positive impact on your operations by making the best use of available space and significantly improving both processes and service levels.

Large ASRS cold storage facilities have seen as much as an impressive 40% increase in throughput and a 70% reduction in labor.

ASRS systems are designed to handle orders efficiently with:

- High Inventory and Shipping Accuracy

- Automated Replenishment

- Less Product and Rack Damage

- Reduced Workforce

- Safer Work Environment

- Decrease in Training

- Less Pick Errors

The innovative and advanced technology of ASRS provides solutions for superior customer value such as:

- Sequencing Buffer

- Goods to Person

- Sorters

- Inventory Storage

- Camera Systems

- Execution Software

- Robotic Picking

- Load Handling Devices

- Auto Store

- Mobile Automation

The final cost of a fully automated storage and retrieval system can vary widely from operation to operation and even from industry to industry. We can help you understand which system is best for you and what it will cost to implement. To request a free consultation call Skyler at 940-366-2231 or email [email protected].